An energy-saving gas-fired condensing steam boiler refers to a gas-fired boiler in which water vapor in the flue gas continuously condenses to release the latent heat of vaporization and this part heat is effectively utilized by the boiler. Its core feature is to make the exhaust temperature of the boiler ≤60℃ through waste heat condensation technology, making full use of the latent heat in the flue gas, thereby improving the thermal efficiency of the boiler.

Source: GB 24500-2020 "Minimum allowable values of energy efficiency and energy efficiency grades of industrial boilers."

(I) Natural gas composition and calorific value

The main component of natural gas is methane (CH4), high calorific value (HHV) 9500Kcal/Nm³, low calorific value (LHV) 8600Kcal/Nm³

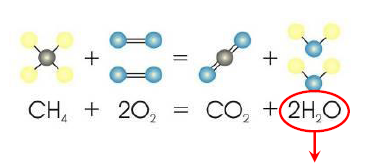

(II) Chemical equation for natural gas combustion

(III) Working principle of condensing boiler By designing flue gas waste heat recovery devices such as economizers, condensers, and air preheaters at the outlet of the gas steam boiler body, the water vapor in the flue gas is condensed from gas to liquid, and the latent heat released by condensation is efficiently utilized, the boiler feed water temperature or the temperature of the combustion air is increased, thereby improving the thermal efficiency of the boiler itself, reducing the consumption of natural gas, saving energy to the greatest extent, reducing fuel costs, and protecting the environment to achieve the goal of sustainable development.

(I) Energy conservation calculation

CH4 + 2O2→ CO2 + 2H2O

16kg 64kg 44kg 36kg

0.7kg x kg

Under standard conditions:

Density of natural gas is 0.7 kg/m3, mass of 1m3 natural gas = 0.7 kg/m3 × 1 m3 = 0.7

16:36=0.7:x

x=36 × 0.7/16=1.575kg

Equivalent to burning 1m3 (0.7kg) of natural gas to generate 1.575kg of water vapor

1.575kg 100℃ water vapor turns into 100℃ water, releasing latent heat:

540.24Kcal × 1.575kg/Kcal = 850.878Kcal of heat

Constant: Under standard atmospheric pressure, 1 kg of 100℃ water vapor turns into 1 kg of 100℃ water, and the heat released is 540.24 Kcal.

(II) Energy-saving analysis of condensing boilers Take a 10-ton gas-fired steam boiler as an example: for an ordinary gas-fired steam boiler, the theoretical gas consumption is 750m³/h, and the low calorific value of natural gas is 8600kcal/Nm³.

Theoretically, if 1m³ of natural gas is completely burned and the water vapor generated is completely condensed, 850.878 Kcal of latent heat can be released. 850.878/8600×100%=9.89%, the theoretical data of the maximum thermal efficiency of condensing gas boilers of 109%. This is an ideal state. It is impossible to condense and absorb all the released water vapor. Actual operating experience has shown that the actual effective utilization of latent heat is 6% to 8%

The latent heat released by a 10T boiler in one hour = 750m³ × 850.878Kcal/m³=638158Kcal. 638160Kcal/8600Kcal=74.2m³. Theoretically, if the condensation heat released by combustion is completely absorbed for one hour, 74.2m³ of gas can be saved. In actual operation, 50m³ of natural gas can be saved. If it runs for 10 hours a day, 500m³ of gas can be saved. If it runs for 300 days a year, 500 × 300=150,000Nm³ of natural gas can be saved. The energy-saving benefits are very impressive.

|

Item |

Condensing gas boiler |

Ordinary gas boiler |

|

Boiler structure |

Body 2 Pass + Air pre-heater + Economizer + Condenser |

Body 3 Pass +Economizer |

|

Exhaust gas temperature (℃) |

≤60 |

120~150 |

|

Thermal efficiency (%) |

101% |

94 |

|

Gas consumption per ton steam(Nm³) |

70 Nm³ |

75 |

|

Heating surface per ton steam(㎡) |

50 |

40 |

(I) Why the thermal efficiency of condensing boilers can be higher than 100%?

Answer:

According to the positive balance method, the thermal efficiency of the boiler is calculated according to the low calorific value of natural gas, η=Q1/Qr×100%

η is the thermal efficiency of the boiler, Q1 is the effective heat utilization of the boiler, and Qr is the input heat of the boiler = fuel consumption × the low calorific value of natural gas

According to the thermal calculation software, η can reach 95.9% when the heat transfer components of the boiler are arranged reasonably.

The condenser is designed at the tail of the condensing boiler to reduce the flue gas temperature from 100℃ to below 60℃, effectively utilizing the sensible heat and condensation latent heat in the flue gas. This part of the waste heat recovery is converted to a boiler thermal efficiency of 6%. Condensing boiler thermal efficiency = η + condensing system conversion efficiency = 95.9% + 6% = 101.9%. Therefore, the thermal efficiency of the condensing boiler is higher than 100%.

The exhaust gas temperature of the condensing steam boiler is very low. Will it reduce the service life of the boiler?

Answer:

1. The condensing steam boiler developed and produced by Kenuo adopts a two-pass structure for the boiler body, with low welding stress and low metal fatigue strength. Compared with the three-pass structure, the service life is increased by more than 5 years;

2. The condensing steam boiler developed and produced by Kenuo, the two-pass convection heating area is reasonably arranged, and the outlet temperature of the front smoke box at 280℃, which fundamentally solves the problem of flue gas condensation in the boiler body and ensures the service life of the boiler;

3. The condensing steam boiler developed and produced by Kenuo uses corrosion-resistant ND steel material tube + silicon-magnesium-aluminum alloy composite fin material for the economizer and condenser, which not only increases the heat transfer coefficient but also ensures the service life. ND steel, also known as 09CrCuSb (or 09CrCuSbNi) steel, is a special material steel plate that exhibits excellent corrosion resistance in low-temperature environments. Its main component is iron (Fe), which also contains a small amount of chromium (Cr), copper (Cu), antimony (Sb) and nickel (Ni). The addition of these alloy elements gives ND steel excellent resistance to sulfuric acid dew point corrosion.

(I) China national standard documents GB 24500-2020 "Minimum allowable values of energy efficiency and energy efficiency grades of industrial boilers"

(II) Energy efficiency rating of gas boilers under rated operating conditions

|

Fuel type |

Fuel received basic low calorific value(Qnet,v,ar)kJ/Nm³ |

Energy efficiency level |

Ordinary boiler thermal efficiency (%) |

Condensing boiler thermal efficiency (%) |

|

Natural gas

|

According to the actual test value of fuel

|

Level 1 |

96 |

103 |

|

Level 2 |

94 |

101 |

||

|

Level 3 |

92 |

98 |

With continuous advancement in boiler technology, the boiler system of Kenuo offers higher thermal efficiency, greater fuel adaptability, and intelligent control. These innovations not only reduce operational costs but also support sustainable development. Choosing a reliable boiler manufacturer is crucial for long-term performance and savings. Contact us today to learn how our tailored boiler solutions can meet your unique needs and take your energy efficiency to the next level.