| Steam Capacity Range: | 0.5-10 ton/hour, 30-750BHP |

| Fuel Options: | Natural Gas, LPG, LNG, Biogas, Diesel, Heavy Oil, Dual Fuel , Propane , #2 Fuel Oil |

| Steam Pressure: | 1.0MPA-3.82MPA |

| Key Features: |

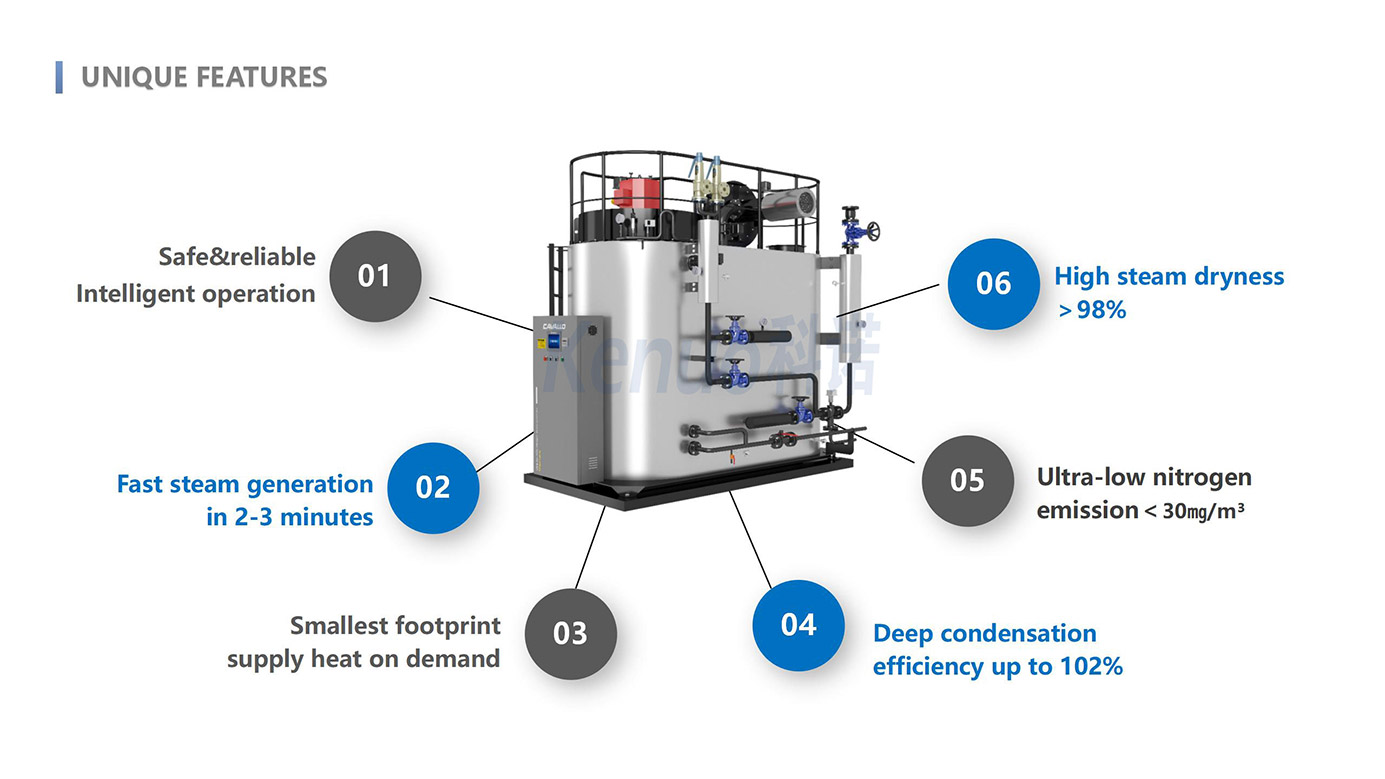

Fast steam generation within 2-3 minutes. External steam-water separator, steam dryness >99% Vertical integrated structure, Minimum boiler room space Coil pipe structure, wide pressure range up to 3.82Mpa Condensing type, 5% higher efficiency than one-though boiler, save fuel cost |

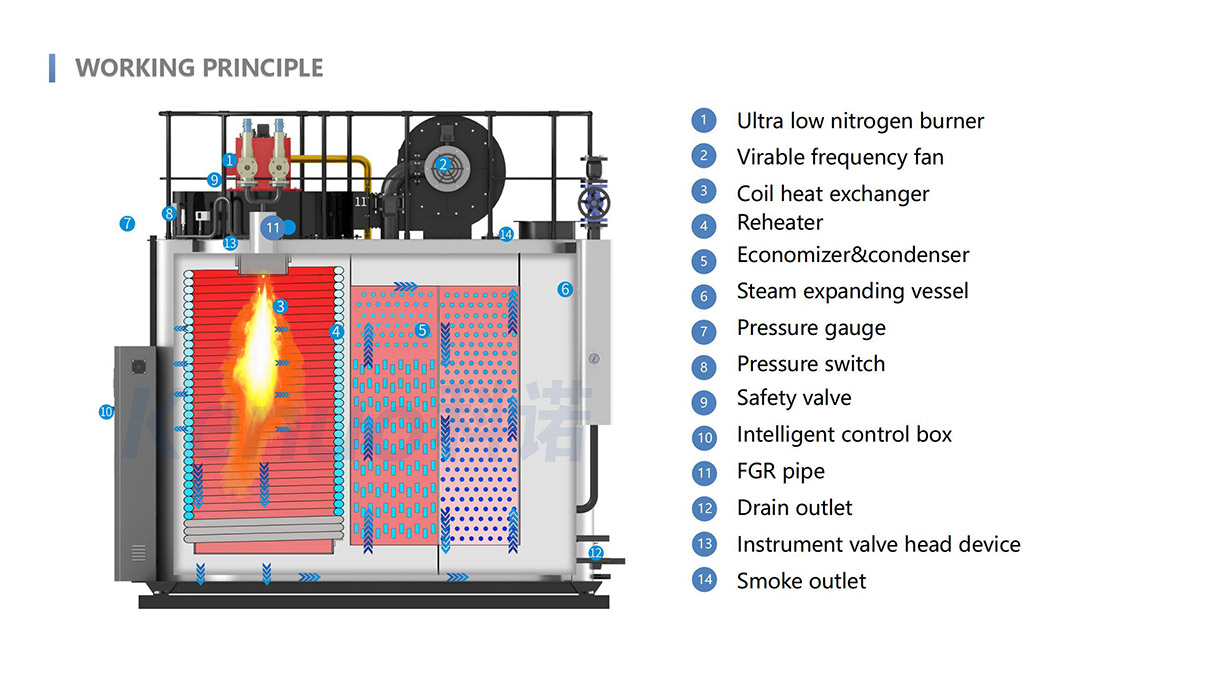

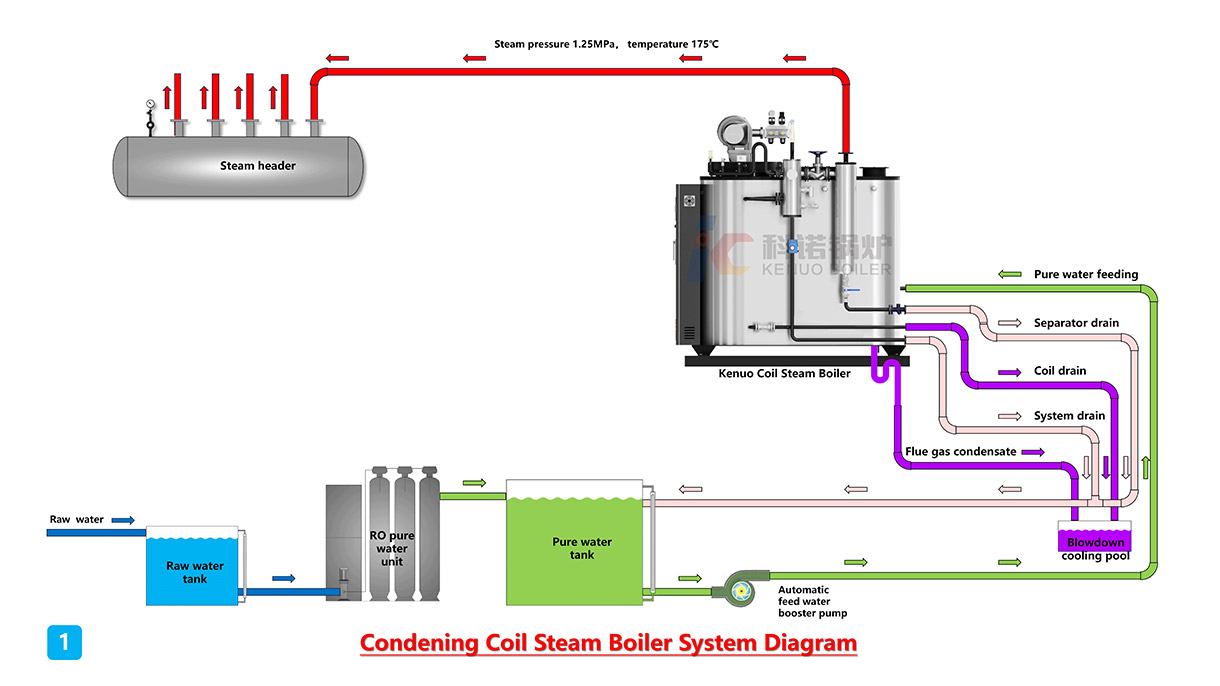

This vertical coil type gas condensing steam boiler is newly developed by Kenuo boiler, has the features of small water volume, safe and reliable performance and fast steam generation. It adopted unique and durable coil structure, inner circulation created super low pressure difference, and smaller thermal stress shock, higher heat efficiency and longer service life. Integrated economizer & condenser, makes boiler very high efficiency up to 103%. Equipped with intelligent controller can realize boiler fullly automatic control.

1.Lower Water quality requirements. Different from traditional water tube steam boiler, Kenuo boiler uses counter-current heat exchange forced circulation technology and high-speed water flow to make the coil less prone to scaling.

2.Fast steam generation, it takes only 2-3 minutes to reach the required working pressure.

3.Adopt coil structure, high thermal efficiency and long service life.

4.Highly integrated structure with burner, controller, condenser, water pump all in one machine, smallest size, save boiler construction investment.

5.Intelligent power-save automatic control (water replenishment as required and stable pressure)

Adopt Swiss brand ADD inverter, perfect combination with combustion fan , feed water pump, and optimized PLC automatic control, boiler load meets the full-proportional personalized output. Wide frequency conversion makes the motor output more power-saving, energy-saving and stepless adjustment.

|

Model |

Rated steam output(TPH) |

Rated working pressure(MPA) |

Rated Steam Temperature(℃) |

Heat Efficiency(%) |

Nox Emission(mg/m³) |

Transportation Weight(ton) |

Overall Dimension(mm) |

|---|---|---|---|---|---|---|---|

|

PGS0.5-0.8-Y(Q) |

0.5 |

0.8 |

175 |

≥101 |

≤80 or ≤30 |

1.4 |

2100*1500*2200 |

|

PGS1-1.25-Y(Q) |

1 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

2.6 |

2500*1700*2800 |

|

PGS1.5-1.25-Y(Q) |

1.5 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

3.5 |

2800*1900*3000 |

|

PGS2-1.25-Y(Q) |

2 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

4.8 |

3400*2200*3300 |

|

PGS3-1.25-Y(Q) |

3 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

6.5 |

3600*2400*3500 |

|

PGS4-1.25-Y(Q) |

4 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

8.7 |

3800*2500*3600 |

|

PGS5-1.25-Y(Q) |

5 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

10.4 |

4000*2700*3800 |

|

PGS6-1.25-Y(Q) |

6 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

11.3 |

4000*2700*3800 |

|

PGS8-1.25-Y(Q) |

8 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

14.5 |

4300*30000*4100 |

|

PGS10-1.25-Y(Q) |

10 |

1.25 |

194 |

≥101 |

≤80 or ≤30 |

18.2 |

4600*3000*4300 |