| Heat Output Range: | 30-1500x 104 kCal/hr, 350KW-14MW/hr |

| Fuel Options: | Natural Gas, LPG, LNG, Biogas, Diesel, Heavy Oil, Dual Fuel , Propane , #2 Fuel Oil |

| Design Pressure: | 0.8-1.1MPA |

| Key Features: |

Inner 3 coils 3 pass structure, high efficiency >96% Wetback structure, durable and long service life over 30 years. Highly integrated with economizer, compact structure and energy saving. Split type burner with VFD fan, Complete combustion, save fuel cost. Reach high temperature upto 350 ℃ at low pressure 1.25Mpa. |

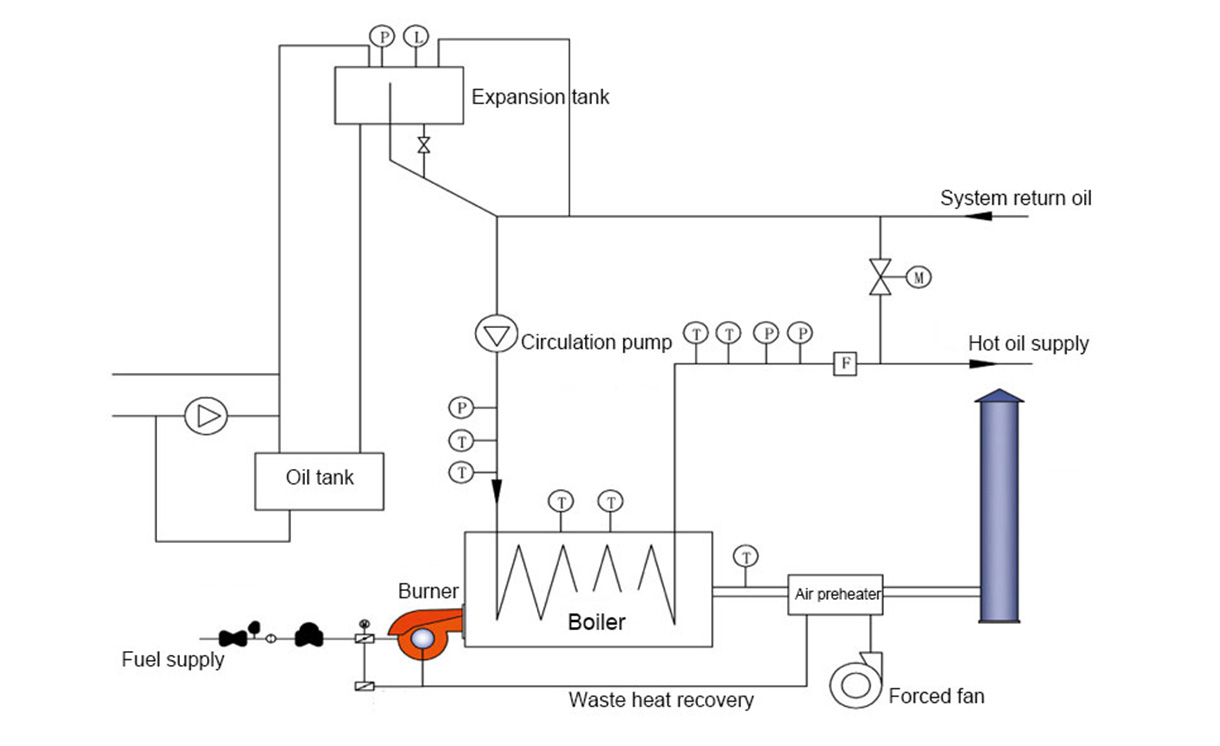

YY(Q)W series horizontal oil-fired gas fired thermal oil boiler adopts 3 coils wetback structure. The main boiler body is composed of an outer coil, a middle coil, an inner coil, between coils is flue gas. After the high-temperature flue gas generated by the combustion radiates heat in the furnace, the high-temperature flue gas convect and releases heat to the middle coil and the outer coil, and then the flue gas is discharged to the atmosphere through the economizer and the chimney. This thermal oil heater uses heat transfer oil as the heating medium. It has a working process of sending heat energy to the heat-using equipment and then returning to the heating furnace for reheating. Compared with steam boiler It can reach a high operating temperature at low pressure and can do high-precision control on the heat medium.

Wood processing industry: Such as plywood factory, timber factory, for process of drying and forming of beaver board, shaving board, laminated sheet, etc.

Building material industry: gypsum board, Asphalt dissolution, concrete heating tank, waterproof material, felt production, etc

Textile printing&dyeing industry for the process of Heat setting, textile printing, ageing, drying, etc.

Plastic and rubber industry: Hot pressing, calendering, extrusion, vulcanization, artificial leather processing, etc.

Chemical industry: Polymerization and condensation reaction, distillation, rectification, concentration, evaporation, fusion

Oil refinery: Lubricating oil production, waste oil refining

|

Model |

Rated thermal power(KW/H) |

Design pressure |

Rated Outlet/inlet Oil Temp.(℃) |

Heat Efficiency(%) |

Max working temp.(℃) |

Transportation Weight(ton) |

Transportation |

|---|---|---|---|---|---|---|---|

|

YY(Q)W-350Y(Q) |

350 |

0.8 |

320/280 |

≥96 |

350 |

2.6 |

Φ1200×2400 |

|

YY(Q)W-700Y(Q) |

700 |

0.8 |

320/280 |

≥97 |

350 |

3.4 |

Φ1700×3000 |

|

YY(Q)W-1500Y(Q) |

1500 |

1.1 |

320/280 |

≥97 |

350 |

4.2 |

Φ1950×4300 |

|

YY(Q)W-1900Y(Q) |

1900 |

1.1 |

320/280 |

≥97 |

350 |

6.8 |

Φ2400×4300 |

|

YY(Q)W-2300Y(Q) |

2300 |

1.1 |

320/280 |

≥97 |

350 |

7.6 |

Φ2520×5300 |

|

YY(Q)W-2900Y(Q) |

2900 |

1.1 |

320/280 |

≥97 |

350 |

9.8 |

Φ2800×6300 |

|

YY(Q)W-3500Y(Q) |

3500 |

1.1 |

320/280 |

≥97 |

350 |

10.2 |

Φ2920×6500 |

|

YY(Q)W-4700Y(Q) |

4700 |

1.1 |

320/280 |

≥97 |

350 |

17.5 |

Φ3230×6700 |

|

YY(Q)W-5900Y(Q) |

5900 |

1.1 |

320/280 |

≥97 |

350 |

24.6 |

Φ3260×7450 |

|

YY(Q)W-7000Y(Q) |

7000 |

1.1 |

320/280 |

≥97 |

350 |

28 |

Φ3260×7900 |

|

YY(Q)W-10500Y(Q) |

10500 |

1.1 |

320/280 |

≥97 |

350 |

37.6 |

Φ3650×10600 |

|

YY(Q)W-14000Y(Q) |

14000 |

1.1 |

320/280 |

≥97 |

350 |

47.2 |

Φ3980×11500 |