| Steam Capacity Range: | 1-30 ton/hour, 60-2100BHP |

| Fuel Options: | Natural Gas, LPG, LNG, Biogas, Diesel, Heavy Oil, Dual Fuel , Propane , #2 Fuel Oil |

| Steam Pressure: | 0.7MPA-3.82MPA |

| Key Features: |

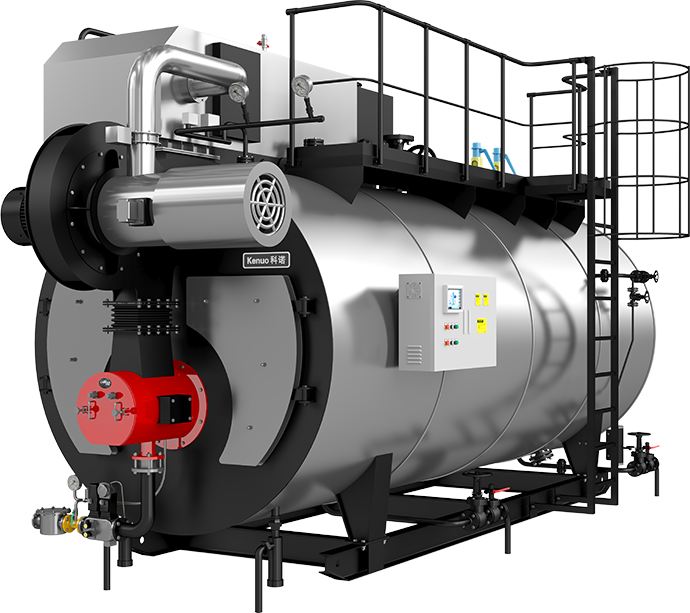

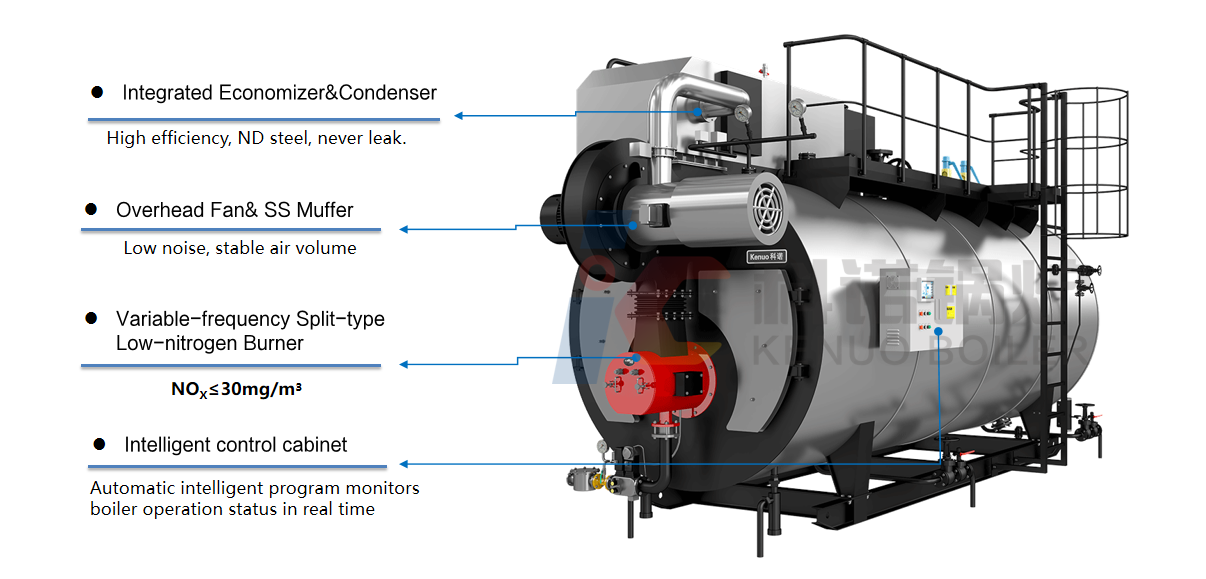

Ultra-high efficiency up to 103% Minimum maintenance almost 0 for boiler body Integrated economizer&condenser, never leak Safe&durable, long service life 30 years Air cooled smoke box without refractory cement |

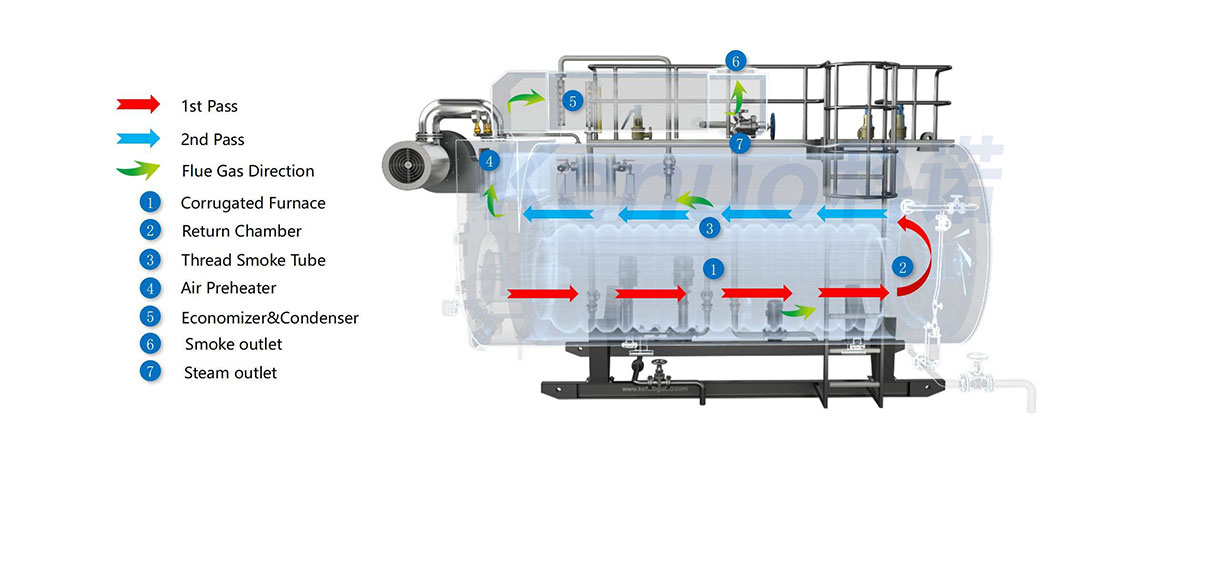

Reversal chamber adopted oval runway shape, compared with traditional round shape,this structure greatly increased steam space, makes the steam dryness up to 99.83%, ensure the steam quality. (Increase the upper steam rising space, steam production space, and steam storage space).

(1) Increase the high temperature area radiation heating surface

(2) Increase the combustion space, full combustion, more energy-saving

(3) Large furnace, diffuse flame, lower nitrogen;

Material:ND Steel+Silicon-magnesium-aluminum alloy fin tub

Feature:Better heat transfer performance and high heat exchange intensity ,Stronger acid corrosion resistance

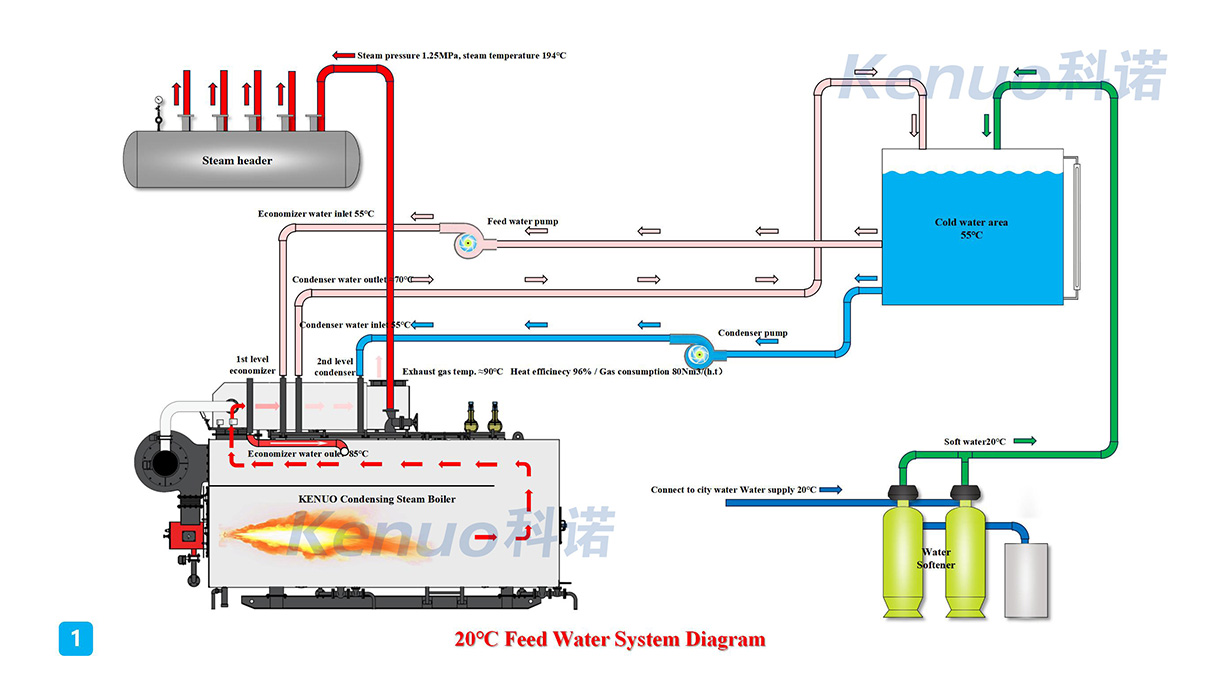

The sensible heat in the flue gas and the latent heat of condensation of water vapor are recovered to the maximum extent, the exhaust temperature is reduced; So the thermal efficiency of the boiler is improved, and NOX emissions are reduced.

(water replenishment as required /stable pressure)

Adopt Swiss brand ADD inverter, perfect combination with combustion fan , feed water pump, and optimized PLC automatic control, boiler load meets the full-proportional personalized output. Wide frequency conversion makes the motor output more power-saving, energy-saving and stepless adjustment.

|

Model |

Rated steam output(TPH) | Rated working pressure(MPA) | Rated Steam Temperature(℃) | Heat Efficiency(%) | Nox Emission(mg/m³) | Transportation Weight(ton) | Overall Dimension(mm) |

|---|---|---|---|---|---|---|---|

|

WNS2-1.25-Y(Q) |

2 |

1.25 |

194 |

≥96 |

≤80/30 |

8.2 |

4960*2140*2340 |

|

WNS3-1.25-Y(Q) |

3 |

1.25 |

194 |

≥96 |

≤80/30 |

9.8 |

5280*2240*2380 |

|

WNS4-1.25-Y(Q) |

4 |

1.25 |

194 |

≥96 |

≤80/30 |

12.9 |

5720*2440*2570 |

|

WNS5-1.25-Y(Q) |

5 |

1.25 |

194 |

≥96 |

≤80/30 |

16.6 |

6200*2700*3900 |

|

WNS6-1.25-Y(Q) |

6 |

1.25 |

194 |

≥96 |

≤80/30 |

17.2 |

6690*2630*2660 |

|

WNS8-1.25-Y(Q) |

8 |

1.25 |

194 |

≥96 |

≤80/30 |

21.5 |

6800*2800*3050 |

|

WNS10-1.25-Y(Q) |

10 |

1.25 |

194 |

≥96 |

≤80/30 |

27.5 |

7250*2900*3250 |

|

WNS12-1.25-Y(Q) |

12 |

1.25 |

194 |

≥96 |

≤80/30 |

30.3 |

7750*3100*3500 |

|

WNS15-1.25-Y(Q) |

15 |

1.25 |

194 |

≥96 |

≤80/30 |

37.5 |

8000*3300*3700 |

|

WNS20-1.25-Y(Q) |

20 |

1.25 |

194 |

≥96 |

≤80/30 |

49.3 |

9050*3500*4050 |

|

WNS25-1.25-Y(Q) |

25 |

1.25 |

194 |

≥96 |

≤80/30 |

57.6 |

9850*3700*4300 |