Gas steam boiler is a steam boiler that uses clean energy natural gas as fuel. It has the characteristics of high thermal efficiency, easy operation, low environmental pollution, and a small footprint. It is widely used in the industrial field. At present, the price of global petrochemical fuels continues to rise, and the operating cost of natural gas boilers is constantly increasing. How to reduce the operating cost has become a common concern of many enterprise owners. Kenuo Boiler has been focusing on energy-saving gas boilers for 30 years and has proposed the following solutions for energy-saving measures for gas steam boilers.

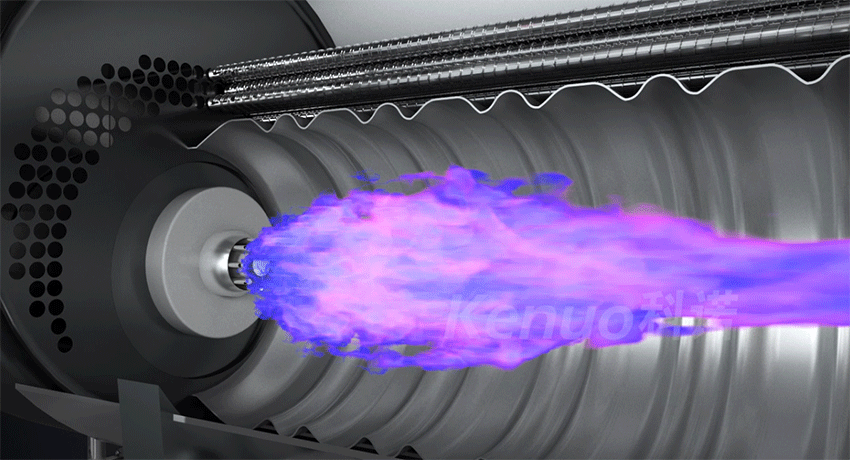

1. The operation adjustment modes of natural gas burners include single-stage fire control, two-stage fire control, mechanical proportional adjustment, electronic proportional adjustment, variable frequency proportional adjustment, etc. Among them, variable frequency proportional adjustment can accurately provide wind pressure and air volume, ensure the air-fuel ratio of each load section, and make combustion more complete, with a burnout rate of up to 99.99%. Kenuo gas boilers are equipped with burners with variable frequency proportional adjustment, which can not only improve combustion efficiency but also save 20% of electricity;

2. Use advanced combustion control systems (BMS), such as Siemens LMV62 and LMV60;

3. Use a flue gas analyzer during debugging to accurately control the air-fuel ratio. The oxygen content is best at 3%~5%, and the CO value is 0mg (the maximum value does not exceed 45mg);

4. Maintain the burner every 3 months, and clean the burner nozzle, ignition electrode, bellows, gas filter, and other components in time.

1. Scientifically and rationally design furnace volume heat load and boiler back pressure;

2. Use efficient heat transfer components: corrugated furnace, threaded smoke pipe, silicon magnesium aluminum alloy fins;

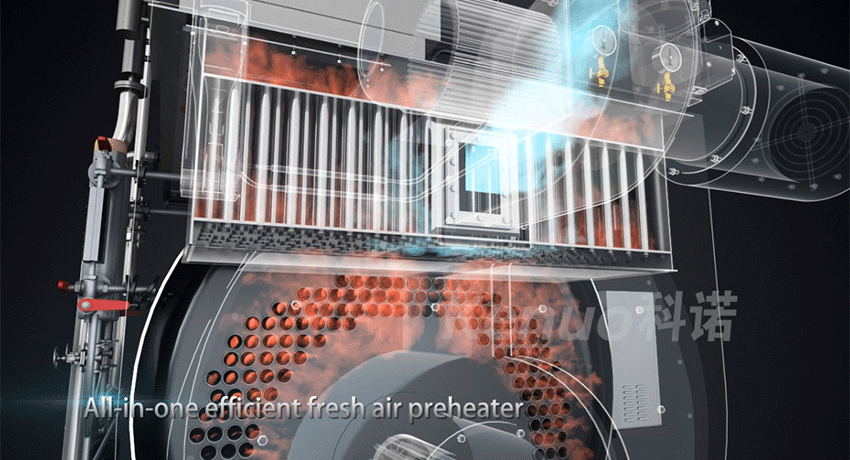

3. By arranging flue gas waste heat recovery devices such as air preheater, economizer, condenser, etc. at the outlet of the boiler body, reduce the boiler's exhaust temperature, increase the combustion fresh air temperature and boiler water supply temperature, reduce exhaust heat loss to the greatest extent, and make full use of the latent heat released by water vapor generated after natural gas combustion. The LNZ-Q series air preheating condensing gas steam boiler designed and developed by Kenuo Boiler has a thermal efficiency of more than 6% higher than that of traditional three-pass boilers and can save 5Nm³ of natural gas per ton of steam.

1. Recycle the condensate generated during the use of steam, and after iron removal and oil removal, return it to the boiler as feed water. Recycling the heat and water resources of the condensate can save 5%-10% of fuel and reduce the cost of water softening;

2. If a large amount of high-temperature condensate is used, the amount of boiler water replenishment will be greatly reduced, resulting in an increase in the boiler exhaust temperature (>150℃), increased flue gas heat loss, and reduced boiler thermal efficiency. So, is there a technical solution that can utilize both the heat of condensate and the heat of flue gas waste heat? So as to achieve energy saving in operation to the greatest extent.

For projects with a large amount of high-temperature condensate recovery in the process, the LNZ-H series rear air preheating condensing gas steam boiler designed and developed by Kenuo Boiler reduces the flue gas temperature to below 70℃ through the waste heat recovery system of the first-stage economizer, second-stage economizer, third-stage air preheater, and fourth-stage condenser, ensuring that there is a process with high-temperature condensate recovery, and the boiler thermal efficiency can still reach more than 98%, which is 6% higher than the thermal efficiency of the traditional three-pass boiler.

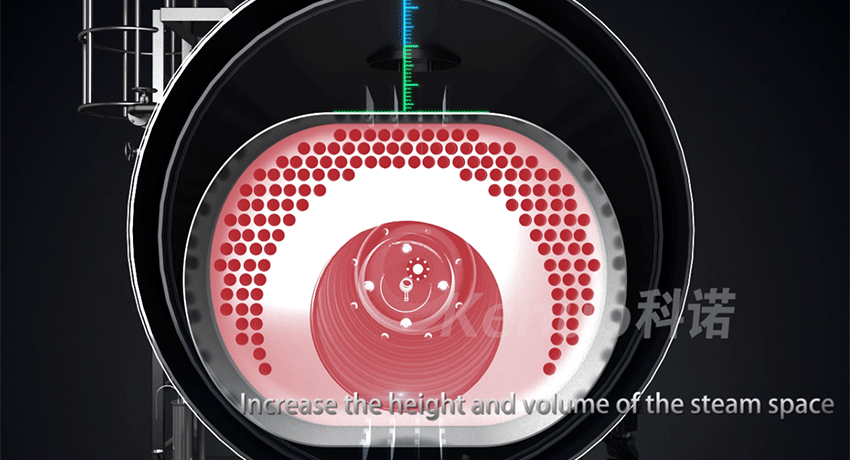

1. Increase steam space in the drum

2. Design a scientific and reasonable steam-water separation device in the drum

3. Increase boiler water circulation rate

Ensure that boiler water quality meets requirements and prevents scale formation. Measures such as softening water equipment, regular water quality testing, and chemical cleaning can be used to improve heat transfer efficiency and reduce fuel consumption.

Generally, the boiler efficiency is higher when operating at the load range of 70%-95%. For processes with a large range of operating load fluctuations, it is necessary to consider using multiple boilers in combination to operate the boiler in the high-efficiency load range.

1. The boiler body is made of high-quality insulation materials, such as aluminum silicate plate + mirror aluminum foil veneer glass wool felt, which can effectively reduce heat loss;

2. The steam pipes and steam headers are insulated;

3. The boiler smoke box is made with refractory castables, and it should be regularly checked for shedding and repaired in time; the front smoke box of the Kenuo boiler adopts an air-cooled jacket design to reduce heat loss, and this type of smoke box maintenance-free for life.

|

Shemostatic team trap |

Float steam trap |

|

|

|

Draining water also steam, wasting heat energy |

Only draining water not steam, reduce heat loss |

The industrial boilers of Kenuo equip with the most advanced technology and high-quality accessories to improve thermal efficiecny and reduce costs for customers. If you are intersted in the customized solutions for your own business, you need to choose the professional boiler manufacturer to provide you with the solutions according to the working conditions. As the leading boiler-manufactuiring company, Kenuo has a great amount of experience in boiler manufactruer and boiler system design. Reach out now to explore how our industrial boilers can optimize your operations.